There are a few designs floating around for replacing this darlington hybrid online, but none of them seem to be very well tested. I created this design by tearing down, measuring and reverse-engineering a fully functional S-603W. The most important change to the design compared to the original hybrid, is the addition of a bias adjustment potentiometer. The resistors are laser-cut in the original hybrids to permanently set bias, and that’s just not practical when manufacturing discrete replacements. You also can’t just copy the original bias resistor value verbatim, as you’re very likely to be using more modern transistors with higher gain than the ones in the hybrid (the original 992/1845 had under 200 hFE – yikes!) The result of copying the values of a hybrid straight off is likely to give you an amplifier with no bias at all, and no way to adjust it.

The transistors used can be pretty much anything. The 992/1845 are a good jellybean choice, but for the following two stages, “any decent >120V hifi driver transistor pair” and “any decent >120V hifi power transistor pair” will work. The ones I used came from a scrapped Onkyo AVR. You might be able to use integrated darlington pairs for the two last stages, at the cost of slightly higher distortion.

Bias

Since the resistor by the diodes ends up being a much higher value than the original design (original in my module was 61 ohm, my potentiometers ended up being set at about 400 ohm), the diodes have less authority over the bias reduction as the heat sinks warm up. Bias is increased by adding more resistance in series with the diodes. This means that the higher the bias is set, the less authority the diodes have to decrease the bias with temperature, and the more likely the module is to thermally run away when it gets hot. For this reason, it’s important to keep bias low. Crossover distortion disappears well below 20 mA bias, so there’s no point setting it higher! Thermal runaway becomes very likely if the bias is set to more than 30 mA when allowed to warm up with no load. 20 mA is about 5 mV across the test points in an Optonica SM-7100.

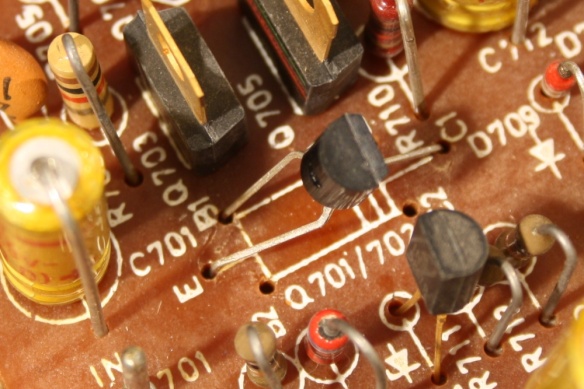

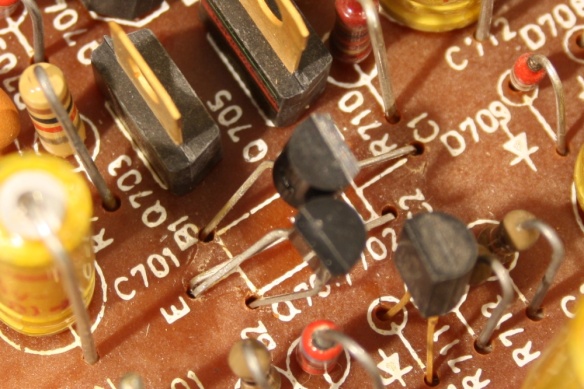

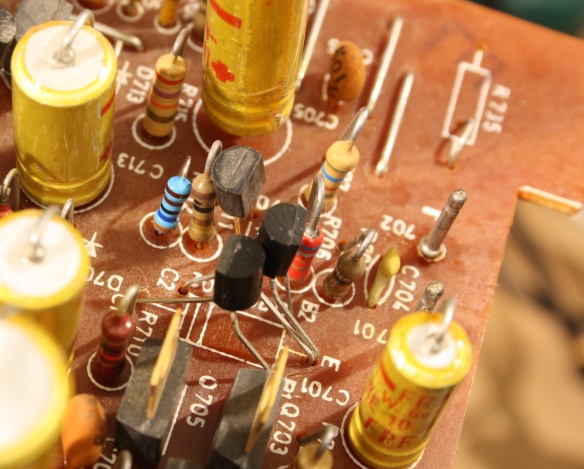

Actually constructing the module was reasonably simple with these transistors since the pinouts are very easy to work with:

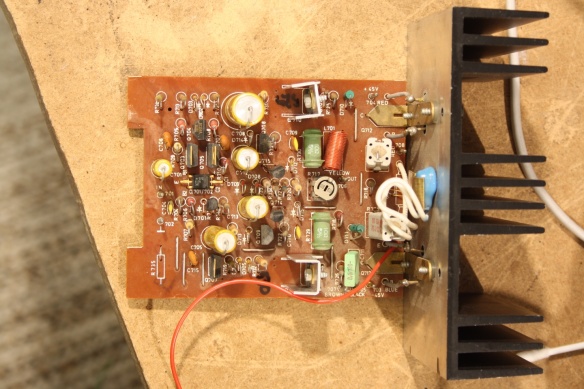

The small copper sheets double as heat sinks for the driver transistors, and serve to couple the base of the right hand side 992 to the other side of the “transistor stack”. The drive transistors turned out not to need any cooling – they run quite cool. The 992/1845 run at about 60 C in normal operation with no cooling, and don’t get much warmer under load.

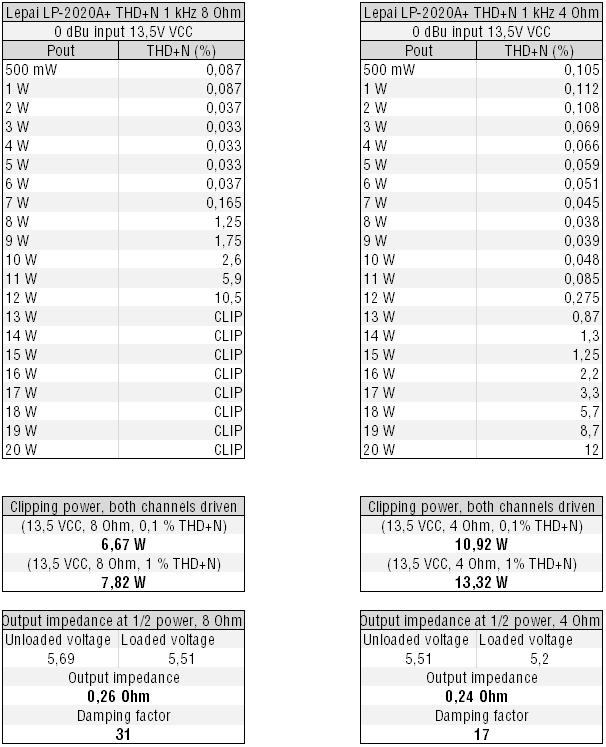

I’ve tested these modules extensively, and they’ve survived continuous rated power, 4-ohm loading and even an output short-circuit. Performance is excellent, and you can find a test report of the finished amplifier here.

Other “fixes”

If you want to cut down on the preamp noise, you can change the power stage feedback resistors R335/R336 (R335 was misprinted as R349 on my PCB, so watch out! It’s the smaller “R349”) from 10K to 8K2 to decrease the amplifier’s gain by a couple of dB, and change the input series resistors R303/R304 from 1K to 10K. These mods combined increase the input impedance to 20k and drop the power amplifier’s gain from 26 dB to 18 dB, which really makes the preamp’s hiss a lot less noticeable, and makes the amp more compatible with modern sources like computers and CD players.

The bass knob is generally quite terrible on this model, adding gain all the way up to 400 Hz. adding a 22 nF film cap across C215 and C214 right next to the bass knob will drop the frequency down a bit, making it sound a bit more pleasant: